OpenBot

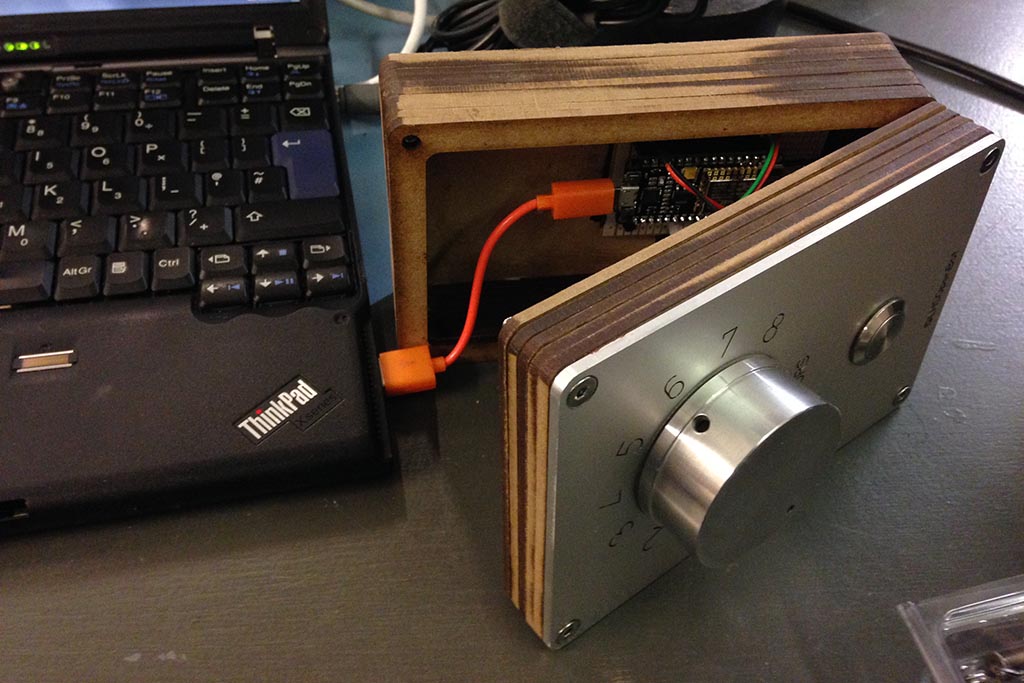

12 Dec 2016With the aim of promoting involvement and upward mobility within Leeds Hackspace I created OpenBot - a small device which tweets how long the space will be open to members for.

With a simple twist of a knob and push of a button OpenBot will shout to the world how long the space will be open for - and thus open to all members, keyholder or otherwise.

Why bother?

Only keyholder members can access the Hackspace 24/7. Non-keyholders can only use the space when there is a keyholder present, or during an open event. In order to gain keyholder privileges it is important to interact with the community and gain trust - something that can be difficult to do when it isn't well advertised that the space will be open.

Motorised potentiometer turns itself

The knob automatically turns itself to indicate how long the space will be open for, every hour rotating counter clockwise to the next setting. This allows people who arrive after the initial announcement to see how long the space will be open for, and if they will be around longer, make a new announcement.

Each minute the software checks the position of the pot and adjusts it if necessary using the built in motor, controlled by a Rohm BD6211F H-bridge. There's a margin of error built in to the movement control system to allow for jitter in the ADC readings, defined by KNOB_VARIANCE in the code.

The motor doesn't turn particularly fast, so no special considerations were taken for making sure that the feedback loop was specially optimised or lightweight.

Front Panel, including a disaster

The slick front panel was designed in Front Panel Designer and machined by Schaeffer AG. The finish is excellent, with a lightly bead blasted, anodised face and sharp engravings for the text. I would definitely recommend using them, even if they are a little expensive. Be aware though, they appear to ship absolutely everything in giant boxes. This 150 mm x 100 mm panel turned up on the neighbour's doorstep one morning in a box the size of a medium sized suitcase. I wish I had taken a photograph of it.

The cut-outs were perfect, except for one slight problem. When I submitted the job at 2:00 AM one Sunday morning I forgot to delete the hole I was using to indicate the diameter of the knob.

So they cut it out for me.

Instead of a two small holes for the potentiometer spindle and locating lug in the centre of the panel there was a huge, gaping hole. Damnit.

The newest version of the software allows you to mark a hole as "do not cut", but that didn't help me here. Using the lathe I cut out a disc of aluminium and faced it flat, turning a register to the required 50 mm diameter to fit into the opening I stupidly left in the face. The potentiometer fits into two holes I drilled manually, and the plug was secured in place with metal epoxy. This needed to be filed somewhat to fit the custom potentiometer mounted PCB from OSHPark.

Case, version 3

During the prototype phase the case was a poorly constructed MDF box, held together with hot glue and inappropriately placed wood screws. This lasted well enough for getting user feedback and once the machined front panel arrived it was replaced with a more durable laser cut laminated construction. This did relegate the status LED to the bottom of the case, embedded in the wood, making it less visible.

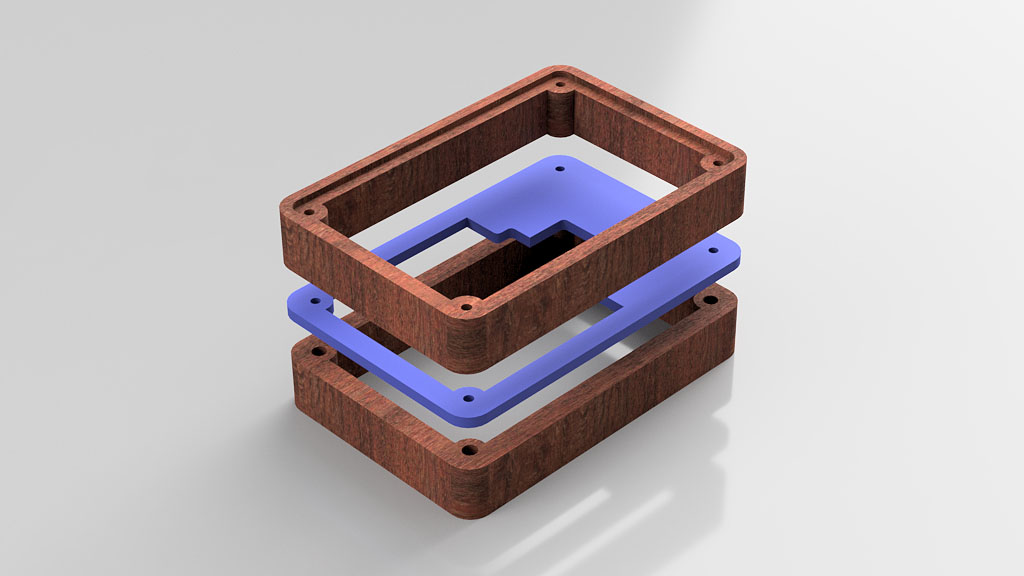

With the advent of the Hackspace's CNC machine it will be possible to create the ideal case. Designed in Autodesk Fusion 360 the model could be taken straight from CAD to CAM. Each layer is a maximum thickness of 25 mm, so I've bought a 28 mm long two flute end mill from China.

The blue slice is a 5 mm thick light guide which takes the red and green high brightness LEDs mounted on the PCB and routes the light to the outside edge. This will be clear acrylic in the end product, but is coloured opaque blue here so that it is easily visible on the render.

On the lower wooden slice larger holes in the corners accommodate M4 threaded wood inserts which, along with some long countersunk machine screws, hold the entire thing together. Watch this space for the final version.